A container user should be aware of the most

important structural differences between containers. Users are

responsible for making the appropriate preparations for

packing and securing cargo. Exterior markings provide container

loading capacity.

We will describe the fundamental components and design of standard box containers.

Basic Container Frame

The load-carrying element of all box containers is a steel

framework, consisting of four corner posts and two bottom side

rails, two top side rails, two bottom cross members, a front top

end rail and a door header.

Bottom Cross Members

Bottom cross members serve as supports for the container floor.

Additional bottom cross members are fitted between the bottom

side rails, to serve as supports for the floor covering.

Side and End Walls

The side and end walls are the components of a

standard box container which are capable of bearing the least

load. Most walls are constructed of 12-16 gauge steel.

Roof Panel

Roof panels are normally constructed of the same materials used for the walls

and are designed to prevent water from pooling on the

top of the container. When containers

are stacked, the load is placed on the corner posts and a

reinforced panel located at each corner, not on the roof

panel.

While the roof panel will normally support several hundred

pounds, WALKING ON THE ROOF PANEL IS NOT RECCOMMENDED. Load bearing

capacity varies by container construction, age and condition.

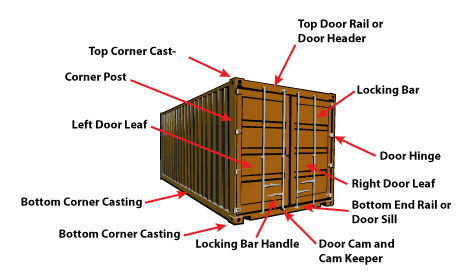

Essential Container Components

The following figure illustrates the essential components

of standard box containers. Additional components include the

door bar handles and the locking components required for sealing.

Standardization of container components and dimensions

allows for the use of standard handling equipment and

transportation. The majority of

containers used for maritime transport are constructed according to

ISO standards. ISO corner castings are a key component.

| ISO Corner

Castings |

|

|